| Chinese

| Chinese

- Home

- Intro

About JiaheDevelopment History

- News

- Products

Shafted Helical FlightsShaftless Helical FlightsShafted Screw Assemblies

Products

Screw Surface Treatments

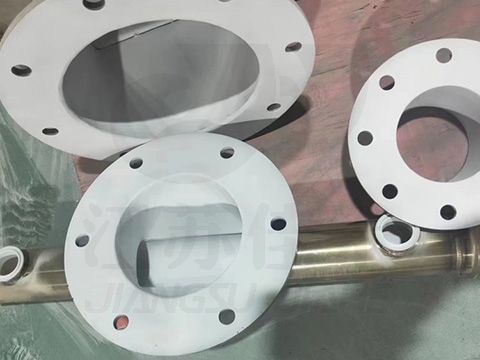

Ceramic-Coated Screw Flight

Alumina ceramic-coated flights (HRC 65+) for highly abrasive materials. 8-10x lifespan vs uncoated s···Price:Custom PricingCustomizedProduct Details

Ceramic-Coated Screw Flight - Advanced Wear-Resistant Conveying Solution

Product Overview

The Ceramic-Coated Screw Flight is a high-performance wear-resistant component designed for heavy-duty material handling applications. Developed by Jiahe Conveying Equipment Technology Co., Ltd, this innovative product combines the structural strength of high-grade steel with the exceptional abrasion resistance of advanced ceramic coatings, significantly extending the service life of screw conveyors in harsh operating environments.

Key Features

1. Superior Wear Resistance

Alumina Ceramic Coating: The screw flight surface is protected by a dense layer of 92%-96% alumina ceramic, offering hardness up to HRA88-90 (equivalent to HRC70+), which is 5-10 times more wear-resistant than hardened steel.

Impact-Resistant Design: Special ceramic tile arrangement and shock-absorbing adhesive layer prevent ceramic detachment under high-impact conditions.

2. Extended Service Life

10-15x Longer Lifespan: Compared to standard carbon steel flights, our ceramic-coated versions last significantly longer when conveying abrasive materials like cement, fly ash, or mineral ores.

Maintenance Reduction: Minimizes downtime for flight replacement, reducing operational costs by up to 60% over 5 years.

3. Optimized Material Flow

Low-Friction Surface: Ceramic's smooth surface (Ra ≤ 0.2μm) reduces material buildup and improves conveying efficiency by 15-20%.

Anti-Corrosion Properties: Ideal for wet or chemically aggressive environments where standard flights would corrode.

4. Custom Engineering Solutions

Variable Coating Thickness: 3-15mm ceramic layer options for different abrasion levels.

Modular Design: Replaceable ceramic segments simplify repairs without dismantling the entire screw.

Technical Specifications

Parameter Specification Base Material Q235B/SS304/SS316/65Mn (Customizable) Ceramic Type Al2O3 (92%-96% purity) Coating Thickness 3-15mm (±0.5mm) Bonding Strength ≥15MPa (ASTM C633) Operating Temperature -40°C to 800°C (Special formulations available) Surface Hardness HRA88-90 (Vickers 1300-1500HV) Impact Resistance ≥3.5J/cm² (ASTM D256) Available Diameters 100-3000mm (Custom sizes possible) Applications

Mining & Mineral Processing

Iron ore concentrate conveyance

Coal and lignite handling systems

Copper/nickel tailings transport

Cement & Building Materials

Raw meal and clinker screws

Fly ash and GGBS conveying

Cement silo discharge systems

Power Generation

Bottom ash conveyors

FGD gypsum handling

Biomass fuel feeding systems

Chemical & Metallurgical

Alumina powder transport

Titanium dioxide production lines

Catalyst recovery systems

Installation & Maintenance

Precision Alignment: Our laser-cut base flights ensure perfect concentricity (≤0.5mm runout).

Thermal Expansion Compensation: Special adhesive accommodates differential expansion between metal and ceramic.

Field-Repairable: Damaged ceramic tiles can be replaced onsite with proprietary bonding kits.

Why Choose Jiahe's Ceramic-Coated Screw Flights?

Proven Performance: Over 200 installations in cement plants with documented 7+ years service life.

Custom Engineering: CAD-optimized flight designs for specific materials and flow rates.

Quality Assurance: Each batch undergoes ultrasonic testing (ASTM E797) for coating integrity.

Cost Efficiency: ROI typically achieved within 12-18 months through reduced maintenance.

For demanding applications where abrasion destroys conventional screw flights, our ceramic-coated solution delivers unmatched durability and operational reliability. Contact our engineering team for application-specific recommendations and performance guarantees.

More products

-

PTFE Coated Helical Flight

PTFE Coated Helical Flight -

Variable Diameter & Pitch Helical Screw Assembly

Variable Diameter & Pitch Helical Screw Assembly -

Mixing Agitator Helical Screw Assembly

Mixing Agitator Helical Screw Assembly -

Hollow Helical Screw Assembly

Hollow Helical Screw Assembly

Precision helicoidal flight manufacturer: 24/7 engineering support at +86 400 990 1585 for bulk handling solutions.

Contact us

Address:No. 3, Garment Road, Xuyi County, Huai'an City, China

Landline:+86-517-88296312 / Fax:+86-517-88296316

Email:jiahecom-com@foxmail.com / WeChat:18014145221

Hotline:+86-400-990-1585 (✦ 24/7 Global Support ✦)

Copyright © 2016-2025 Jiahecom.com(Jiahe Conveying Equipment Technology Co., Ltd.), All Rights Reserved. - News

OICQ Online

OICQ Online +86-400-990-1585

+86-400-990-1585