| Chinese

| Chinese

- Home

- Intro

About JiaheDevelopment History

- News

- Products

Shafted Helical FlightsShaftless Helical FlightsShafted Screw Assemblies

Products

Screw Surface Treatments

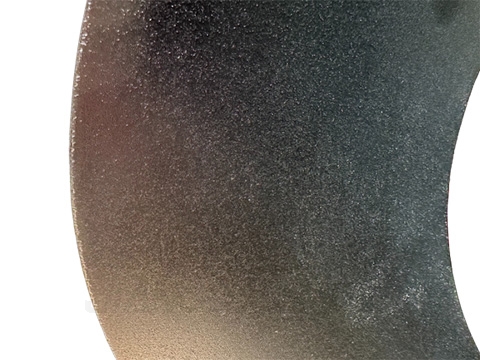

PTFE Coated Helical Flight

FDA-compliant PTFE coating prevents material adhesion. Perfect for sticky foods, chemicals, and phar···Price:Custom PricingCustomizedProduct Details

PTFE Coated Helical Flight – Superior Non-Stick & Corrosion-Resistant Conveying Solution

Product Overview

The PTFE Coated Helical Flight is an advanced material handling component designed for industries requiring non-stick, low-friction, and chemical-resistant screw conveyor systems. Manufactured by Jiahe Conveying Equipment Technology Co., Ltd, this innovative product features a polytetrafluoroethylene (PTFE) coating that significantly enhances performance in sticky, corrosive, or high-purity applications.

Key Features

1. Exceptional Non-Stick Properties

Ultra-Low Surface Energy: PTFE coating prevents material buildup, ensuring smooth flow of sticky substances like adhesives, food products, and polymers.

Reduced Friction: Coefficient of friction as low as 0.04-0.1, minimizing energy consumption and wear.

2. Superior Chemical Resistance

Inert to Most Chemicals: Resistant to acids, alkalis, solvents, and aggressive media (pH 0-14).

Ideal for Corrosive Environments: Perfect for chemical processing, pharmaceuticals, and wastewater treatment.

3. High-Temperature & Hygienic Performance

Wide Temperature Range: Stable from -200°C to +260°C (short-term up to 300°C).

FDA & EU Compliant: Meets food-grade (FDA 21 CFR 175.300) and pharmaceutical standards.

4. Customizable Solutions

Multiple PTFE Grades: Virgin, filled (glass, graphite), or conductive PTFE options.

Precision Coating Thickness: 50-500μm (±10μm tolerance) for optimal performance.

Technical Specifications

Parameter Specification Base Material Carbon Steel, Stainless Steel (304/316), Aluminum Coating Type Pure PTFE, Glass-Filled PTFE, Conductive PTFE Coating Thickness 50-500μm (Customizable) Surface Hardness Shore D 50-65 Coefficient of Friction 0.04-0.1 Operating Temperature -200°C to +260°C Peel Strength >5 N/cm (ASTM D903) Available Diameters 100mm – 2500mm (Custom sizes available) Applications

Food & Beverage Industry

Dough, chocolate, and candy conveyors

Sugar, flour, and powder handling

High-purity food-grade applications

Chemical & Pharmaceutical

Aggressive chemical transport

Pharmaceutical powder conveying

Corrosive slurry handling

Plastics & Polymers

Adhesive and resin transfer

Thermoplastic pellet feeding

Sticky polymer processing

Waste & Water Treatment

Sludge dewatering screws

Chemical dosing systems

Corrosion-resistant wastewater conveyors

Installation & Maintenance Benefits

Easy-Clean Surface: Reduces cleaning time by up to 70% compared to uncoated flights.

Long-Term Durability: 3-5x lifespan extension in corrosive/sticky environments.

Hygienic Design: Smooth, non-porous surface prevents bacterial growth (EHEDG compliant).

Why Choose Jiahe’s PTFE Coated Helical Flights?

✅ Proven Performance: Hundreds of successful installations in food, chemical, and pharmaceutical industries.

✅ Custom Engineering: Tailored solutions for specific materials, temperatures, and hygiene requirements.

✅ Quality Assurance: 100% coating inspection (thickness, adhesion, porosity testing).

✅ Cost Efficiency: ROI within 12-18 months through reduced downtime and maintenance.For industries where material sticking, corrosion, or contamination are critical concerns, Jiahe’s PTFE Coated Helical Flight delivers unmatched performance and reliability. Contact our technical team for application-specific recommendations.

More products

-

PTFE Coated Helical Flight

PTFE Coated Helical Flight -

Variable Diameter & Pitch Helical Screw Assembly

Variable Diameter & Pitch Helical Screw Assembly -

Mixing Agitator Helical Screw Assembly

Mixing Agitator Helical Screw Assembly -

Hollow Helical Screw Assembly

Hollow Helical Screw Assembly

Precision helicoidal flight manufacturer: 24/7 engineering support at +86 400 990 1585 for bulk handling solutions.

Contact us

Address:No. 3, Garment Road, Xuyi County, Huai'an City, China

Landline:+86-517-88296312 / Fax:+86-517-88296316

Email:jiahecom-com@foxmail.com / WeChat:18014145221

Hotline:+86-400-990-1585 (✦ 24/7 Global Support ✦)

Copyright © 2016-2025 Jiahecom.com(Jiahe Conveying Equipment Technology Co., Ltd.), All Rights Reserved. - News

OICQ Online

OICQ Online +86-400-990-1585

+86-400-990-1585