| Chinese

| Chinese

- Home

- Intro

About JiaheDevelopment History

- News

- Products

Shafted Helical FlightsShaftless Helical FlightsShafted Screw Assemblies

Products

Shafted Helical Flights

Segmented Equal-Thickness Screw Flight

Jiahe's segmented equal-thickness screw flights feature interchangeable sections for easy maintenanc···Price:Custom PricingCustomizedProduct Details

Segmented Equal-Thickness Screw Flight

Product Overview

The Segmented Equal-Thickness Screw Flight is a high-performance component designed for screw conveyors, mixers, and other bulk material handling systems. Unlike traditional continuous spiral flights, this segmented version features uniform thickness across its entire length, ensuring enhanced durability, consistent performance, and reduced wear. It is widely used in industries requiring precise material transportation, such as agriculture, mining, cement, food processing, and chemical production.

Key Features

Uniform Thickness Design – Ensures even wear distribution, extending service life.

Segmented Structure – Allows easy replacement of damaged sections without dismantling the entire screw conveyor.

High-Strength Materials – Manufactured from carbon steel, stainless steel, or wear-resistant alloys for superior durability.

Precision Manufacturing – CNC-formed for consistent pitch and smooth material flow.

Corrosion & Abrasion Resistance – Ideal for harsh environments, including wet, corrosive, or high-temperature conditions.

Customizable Dimensions – Available in various diameters, pitches, and thicknesses to match specific application needs.

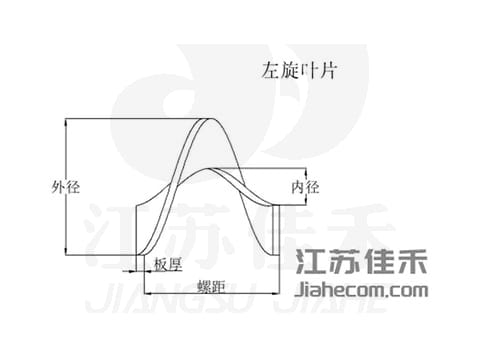

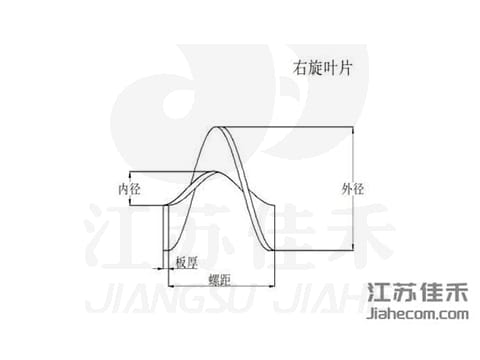

Technical Specifications

Parameter Range Outer Diameter (OD) 100mm – 2000mm Pitch 0.5D – 1.5D (D = Screw Diameter) Thickness 4mm – 30mm Material Carbon Steel (Q235), Stainless Steel (304/316), Hardox, AR400 Surface Treatment Galvanized, Powder-Coated, Hard-Faced, or Polished Connection Method Welded, Bolted, or Keyed Shaft Attachment Applications

Agriculture: Grain handling, feed processing, fertilizer distribution.

Mining & Minerals: Coal, ore, sand, and gravel transportation.

Cement & Construction: Raw material feeding, clinker conveying.

Food Processing: Sugar, flour, spices, and powdered ingredients.

Chemical Industry: Plastic pellets, fertilizers, and abrasive powders.

Waste Management: Sludge, biomass, and recycling material handling.

Advantages Over Conventional Screw Flights

Reduced Maintenance Costs – Damaged segments can be replaced individually.

Improved Efficiency – Uniform thickness minimizes material buildup and blockages.

Longer Lifespan – High wear resistance ensures prolonged operation in abrasive environments.

Flexible Installation – Suitable for both horizontal and inclined screw conveyors.

Customization & OEM Services

At Jiahe Conveying Equipment Technology Co., Ltd, we offer tailored solutions to meet unique operational demands. Our engineering team can design segmented equal-thickness screw flights based on your specific requirements, including:

Material Selection (Carbon Steel, Stainless Steel, Abrasion-Resistant Alloys)

Special Coatings (Anti-Corrosion, Non-Stick, or High-Temperature Resistant)

Non-Standard Dimensions (Custom diameters, pitches, and segment lengths)

Why Choose Jiahe Conveying?

20+ Years of Industry Experience – Trusted by global clients for reliable conveying solutions.

Advanced Manufacturing Technology – Precision CNC forming and robotic welding ensure high-quality output.

Strict Quality Control – ISO-certified production with rigorous testing for durability and performance.

Global Supply Network – Fast delivery to Europe, North America, Asia, and beyond.

For inquiries, contact us today to discuss your project requirements!

More products

-

PTFE Coated Helical Flight

PTFE Coated Helical Flight -

Variable Diameter & Pitch Helical Screw Assembly

Variable Diameter & Pitch Helical Screw Assembly -

Mixing Agitator Helical Screw Assembly

Mixing Agitator Helical Screw Assembly -

Hollow Helical Screw Assembly

Hollow Helical Screw Assembly

Precision helicoidal flight manufacturer: 24/7 engineering support at +86 400 990 1585 for bulk handling solutions.

Contact us

Address:No. 3, Garment Road, Xuyi County, Huai'an City, China

Landline:+86-517-88296312 / Fax:+86-517-88296316

Email:jiahecom-com@foxmail.com / WeChat:18014145221

Hotline:+86-400-990-1585 (✦ 24/7 Global Support ✦)

Copyright © 2016-2025 Jiahecom.com(Jiahe Conveying Equipment Technology Co., Ltd.), All Rights Reserved. - News

OICQ Online

OICQ Online +86-400-990-1585

+86-400-990-1585